Beyond Dawlish

How to Set Up a PDMS Project: A Step-by-Step Guide

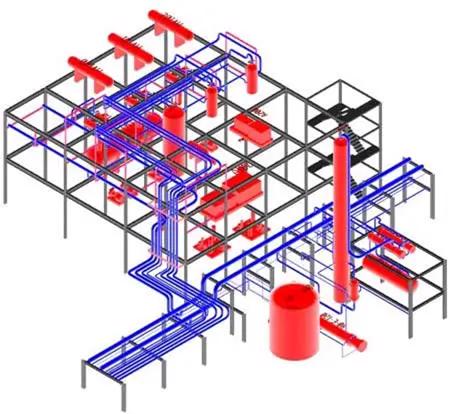

Setting up a PDMS Project (Plant Design Management System) is necessary for efficient plant design and engineering. A well-configured PDMS environment improves collaboration, reduces errors, and enhances project execution. Below is a structured approach to implementing a PDMS Project, covering main aspects like system setup, configuration, and workflow optimization.

For professionals looking to master plant design and PDMS software, enrolling in a PDMS Course can provide hands-on training in 3D modeling, database configuration, and design validation. Gaining expertise in PDMS is crucial for industries like oil & gas, power, and manufacturing, where efficient plant design plays a vital role in operational success.

Why PDMS Project?

A PDMS Project (Plant Design Management System) is essential for industries involved in large-scale plant engineering, such as oil & gas, power plants, chemical processing, and manufacturing. It enables teams to design, model, and manage plant components efficiently within a collaborative 3D environment.

Benefits of Using PDMS for Plant Design

- Enhanced Collaboration – Multiple users can work on the same project simultaneously, improving coordination.

- 3D Visualization & Clash Detection – Helps detect design errors early, reducing costly modifications.

- Standardized Components & Libraries – Ensures consistency in design and compliance with industry standards.

- Automated Reporting & Documentation – Generates accurate Bills of Materials (BOMs), layouts, and design reports.

- Seamless Integration – Works with external CAD, simulation, and structural analysis tools.

Step-by-Step PDMS Project Setup

Setting up a PDMS Project (Plant Design Management System) is essential for efficient plant design and engineering. A well-configured PDMS environment enhances collaboration, reduces errors, and improves project execution.

1. Define Project Scope & Requirements

- Identify project objectives and deliverables.

- Determine the software and hardware requirements.

- Assign roles and access permissions for team members.

2. System Installation & Configuration

- Install PDMS software and required plugins.

- Configure the database for storing design models.

- Integrate with external CAD and simulation tools.

For professionals looking to master plant design, enrolling in a PDMS Course can help. PDMS expertise is in high demand across oil & gas, power, and manufacturing industries, making it a valuable skill for engineers and designers.

3. Project Database Setup

|

Component |

Configuration |

Purpose |

|

Design Modules |

Hierarchical Structure |

Organize 3D Models |

|

Spec Library |

Material Properties |

Standardize Components |

|

Admin Console |

User Access Levels |

Role-Based Permissions |

Efficient database management ensures faster data retrieval and smooth collaboration across disciplines.

4. 3D Modeling & Design Integration

- Import plant layout and component libraries.

- Use parametric modeling for piping, electrical, and structural elements.

5. Load and Manage Components

- Utilize intelligent components for automation.

- Implement revision tracking for design changes.

- Optimize model rendering for large-scale projects.

The Altium Certification Course is highly sought after by PCB designers. Learning Altium helps professionals meet the rising demand in electronics manufacturing, making it an essential skill for those in the industry.

6. Collaboration & Documentation

|

Feature |

Purpose |

Tools Used |

|

Multi-user Access |

Real-time Collaboration |

Cloud-based PDMS |

|

Report Generation |

Generate BOM & Layouts |

PDMS Report Manager |

|

Review & Approval |

Track Design Revisions |

3D Review Tools |

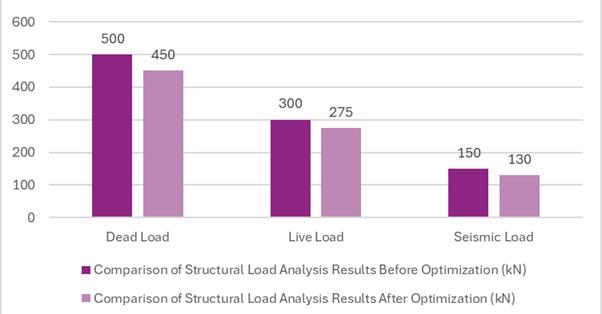

7. Structural & Load Analysis

- Integrate load calculations using ETABS for accurate structural analysis.

- Simulate stress distribution and factor in wind/seismic loads.

- Generate structural reports for approval.

Mastering the ETABS Course is a game-changer for civil engineers. With rapid urban expansion, ETABS expertise is crucial for designing earthquake-resistant structures and ensuring structural integrity in modern construction projects.

8. Final Validation & Project Handover

- Conduct a final design review and quality check.

- Export 3D models and reports for client approval.

- Train end-users on project maintenance and updates.

The Altium Certification Course plays a crucial role in modern electronics design, helping engineers enhance PCB layout skills, circuit simulations, and hardware development for high-efficiency electronic systems.

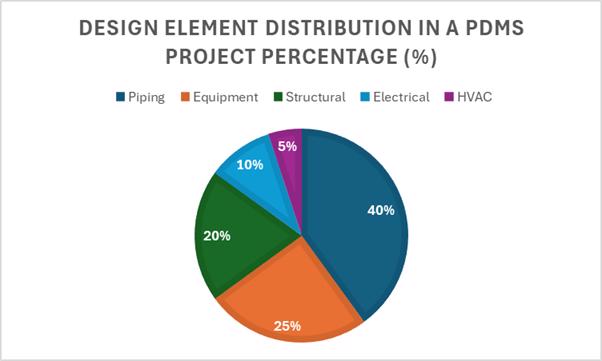

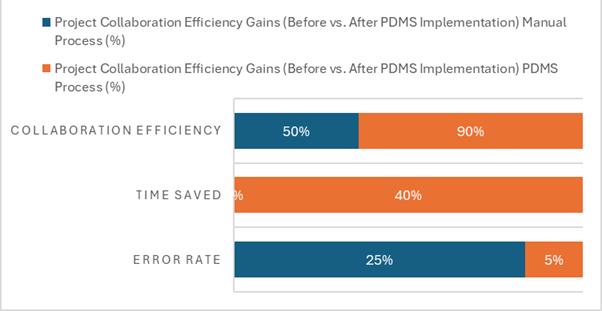

PDMS Project Success Metrics

|

Metric |

Before PDMS |

After PDMS |

Improvement (%) |

|

Design Revisions |

12 |

5 |

58% |

|

Collaboration Efficiency |

60% |

95% |

58% |

|

Project Completion Time |

18 Months |

12 Months |

33% |

Conclusion

Implementing a PDMS Project requires a structured approach involving installation, database configuration, 3D modeling, collaboration, and final validation. By following these steps, organizations can streamline plant design processes, reduce errors, and improve efficiency. Leveraging tools like Altium for PCB design and ETABS for structural analysis further enhances project success.