Beyond Dawlish

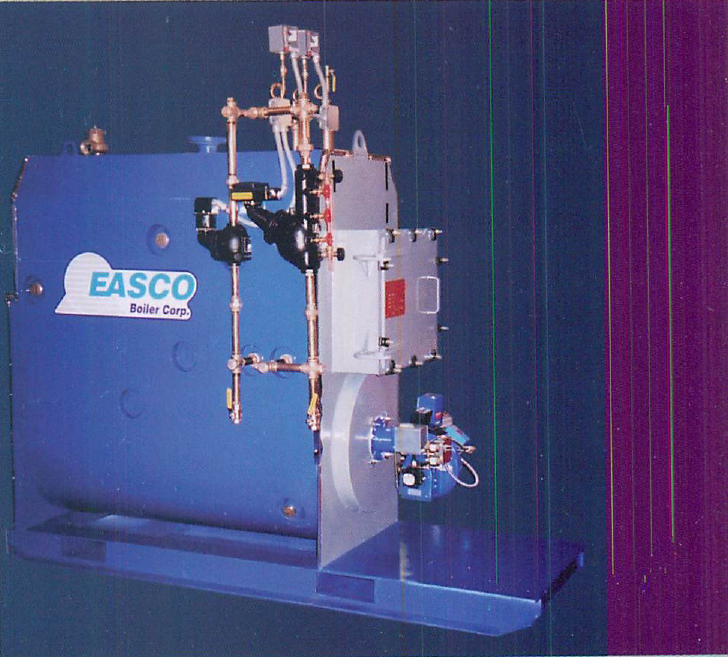

Steam boilers were a cornerstone of industrial progress for the reason that dawn of the Industrial Revolution, powering factories, heating homes, and using generators with the easy but effective pressure of steam. For centuries, these systems depended on manual oversight and mechanical ingenuity. But these days, a brand new generation is unfolding—one wherein smart generation is transforming steam boilers into clever, efficient, and safer machines. From sensors and automation to synthetic intelligence (AI) and the Internet of Things (IoT), smart innovations are redefining how boilers operate, slashing expenses, boosting performance, and aligning with a sustainable destiny. In this weblog, we’ll explore how these advancements are revolutionizing steam boiler systems and what they imply for industries global.

The Evolution of Steam Boilers

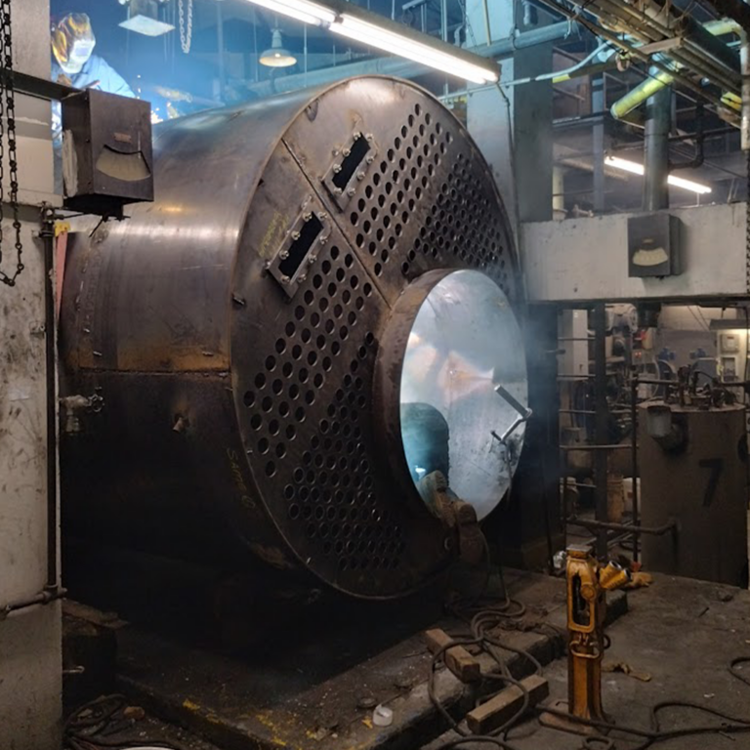

To recognize the smart revolution, permit’s glance again at steam boilers’ history. Early models were crude, vulnerable to explosions, and demanded consistent human intervention. Over time, improvements like strain gauges, safety valves, and automated burners made them extra dependable. Yet, even cutting-edge boilers—before the clever tech wave—depended closely on periodic exams and reactive maintenance. If a tube corroded or a burner faltered, operators frequently didn’t understand until efficiency dropped or a failure befell. This reactive method turned into highly-priced, unstable, and inefficient.

Enter clever generation. By integrating digital gear, boilers are moving from passive workhorses to proactive systems that reveal themselves, predict issues, and optimize overall performance in actual time. This isn’t just an upgrade—it’s a paradigm shift reshaping business operations.

The Building Blocks of Smart Boiler Systems

Smart generation isn’t a single system; it’s a suite of improvements working in concord. Here’s how the important thing additives are revolutionizing steam boilers:

1. Sensors and IoT Connectivity

At the heart of clever boilers are sensors—tiny devices tracking the whole lot from stress and temperature to water exceptional and fuel go with the flow. Connected thru the Internet of Things (IoT), these sensors send actual-time statistics to centralized systems or cloud platforms. Imagine a boiler “speaking” to its operators, reporting a slight strain spike before it becomes a trouble. IoT connectivity ties all of it together, allowing faraway tracking from anywhere—whether or not a manipulate room or a manager’s cellphone halfway across the globe.

2. Automation and Control Systems

Gone are the days of manually tweaking valves. Smart boilers use advanced manipulate structures to modify operations routinely. If a sensor detects low water tiers, the device triggers a feed pump. If combustion performance dips, it exceptional-tunes the air-gasoline mix. Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS) orchestrate those responses, ensuring precision that human arms can’t match. This automation reduces mistakes and continues the boiler strolling at top efficiency.

3. Artificial Intelligence and Machine Learning

AI takes smart boilers to the next degree by means of mastering from information. Machine studying algorithms examine ancient performance—say, how a boiler responds to load adjustments or fuel types—and are expecting future behavior. If a sample indicates a tube might fail in six months, AI flags it early, scheduling preservation before a breakdown. This predictive protection slashes downtime and restore expenses, turning guesswork into approach.

4. Digital Twins

A digital dual is a virtual replica of a bodily boiler, up to date in actual time with sensor records. Engineers can simulate situations—like growing steam call for or switching fuels—without touching the real gadget. This era allows optimize settings, test improvements, and troubleshoot troubles truely, minimizing dangers and maximizing efficiency.

5. Cloud Computing and Data Analytics

Smart boilers generate mountains of statistics, and cloud platforms store and method it efficiently. Analytics gear crunch the numbers, recognizing trends like gradual scale buildup or burner wear. Dashboards present this data in consumer-pleasant visuals, empowering operators to make knowledgeable selections speedy. Cloud get entry to also method specialists can weigh in remotely, enhancing collaboration throughout teams or facilities.

The Benefits of Smart Steam Boilers

These technologies aren’t just flashy accessories—they deliver tangible blessings that redefine boiler operations:

1. Enhanced Efficiency

Smart structures optimize each factor of a boiler’s overall performance. Sensors come across inefficiencies—like extra warmness loss or suboptimal combustion—and automation corrects them immediately. Studies suggest smart controls can enhance performance with the aid of 10-20%, cutting gasoline costs considerably. For a massive industrial boiler burning $500,000 in fuel yearly, that’s a ability $50,000-$one hundred,000 savings—cash that drops straight to the bottom line.

2. Predictive Maintenance

Traditional upkeep is like gambling whack-a-mole—fixing issues as they pop up. Smart tech flips the script. By predicting disasters—say, a pump wearing out or a valve sticking—operators can act proactively. This reduces unplanned outages, which can price lots according to hour in lost production, and extends equipment lifespan, delaying pricey replacements.

3. Improved Safety

Safety is paramount with boilers, given their high-stress, high-heat nature. Smart structures enhance protection by using catching issues early—overpressure, leaks, or gasoline buildup—and triggering automatic shutdowns if wanted. Alarms alert operators instantly, while far flung monitoring reduces the need for employees to go into hazardous zones. Fewer injuries suggest safer offices and lower legal responsibility.

4. Environmental Sustainability

As industries face pressure to decarbonize, clever boilers help. Optimized combustion reduces gasoline use and emissions like CO%u2082 and NOx. Data analytics pinpoint possibilities to exchange to purifier fuels or combine renewables, aligning with policies and company green goals. A clever boiler isn’t simply efficient—it’s a step towards a purifier planet.

5. Remote Operation and Flexibility

With IoT and cloud tech, boilers may be managed from anywhere. This flexibility proved worthwhile in the course of the COVID-19 pandemic, whilst faraway work surged. It additionally shall we multi-web site companies centralize oversight, making sure consistency across centers. If a boiler in Texas desires tweaking, an expert in New York can regulate it with out boarding a aircraft.

Real-World Impact

The revolution isn’t theoretical—it’s taking place now. A electricity plant in Europe retrofitted its getting older boilers with IoT sensors and AI, cutting gasoline use through 15% and downtime by using 30%. A U.S. Food processor adopted digital twins, optimizing steam output for peak call for and saving $2 hundred,000 yearly. Even small businesses gain—suppose a brewery using smart controls to hold specific temperatures, enhancing product best at the same time as trimming costs. These examples display clever tech scales to any operation, handing over outsized returns.

Challenges to Adoption

Despite the promise, hurdles continue to be. Upfront costs for sensors, software program, and integration can be steep, specially for older boilers requiring retrofits. Small centers would possibly lack the price range or information to jump in. Data security is every other problem—related systems are susceptible to cyberattacks, and a hacked boiler may want to spell catastrophe. Training workforce to use those equipment additionally takes time; a group of workers used to wrenches may withstand keyboards.

Yet, those demanding situations are shrinking. Costs are losing as tech matures—sensors that when price loads now promote for tens. Cybersecurity solutions, like encryption and firewalls, are advancing. And consumer-friendly interfaces make education less complicated, bridging the distance for traditional operators. The long-time period financial savings and safety gains frequently outweigh initial investments, making adoption a no brainer for forward-thinking firms.

The Future of Smart Boilers

The revolution is simply beginning. Emerging traits promise even smarter systems:

-

AI-Driven Autonomy: Fully self reliant boilers that self-diagnose and self-correct.

-

Integration with Renewables: Smart controls syncing boilers with solar or biomass energy.

-

Blockchain for Compliance: Secure logs of emissions and maintenance for regulators.

As 5G networks make bigger, real-time facts will float faster, permitting break up-second adjustments. The end result? Boilers that don’t simply run—they think, adapt, and thrive in a digital age.

Harness Smart Innovation with Supreme Boilers

As smart generation reshapes steam boiler structures, partnering with a ahead-questioning producer is fundamental to staying in advance—and Supreme Boilers grants simply that. Known for mixing modern-day design with reliability, Supreme Boilers offers a lineup equipped to integrate with clever answers. The FPS Series optimizes gasoline performance, ideal for pairing with actual-time sensors, at the same time as the compact FST Series suits area-aware setups with out sacrificing electricity. For tailor-made applications, the ESP Series adapts seamlessly to automation, and the PLW Series brings hot water reliability to smart systems. The SM4 Series and SM5 Series provide Scotch Marine sturdiness, ideal for IoT-driven tracking. With Supreme Boilers, you’re no longer simply adopting smart tech—you’re investing in boilers built to thrive inside the virtual age.

Conclusion

Smart generation is turning steam boilers from static machines into dynamic partners in industrial achievement. Sensors, AI, and IoT aren’t changing the basics—they’re enhancing them, making boilers more secure, greener, and greater efficient than ever. For industries reliant on steam, embracing this revolution isn’t optionally available—it’s a competitive facet. Whether you’re powering a manufacturing unit or heating a health center, smart boilers provide a glimpse right into a future wherein era doesn’t just guide operations—it drives them. As we march towards a extra linked, sustainable international, one aspect’s clean: the steam boiler, that age-antique titan, is getting a exquisite, brainy upgrade.