Beyond Dawlish

Global Mirror Coatings Industry: Key Statistics and Insights in 2025-2033

Summary:

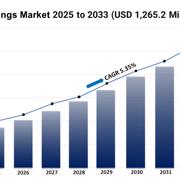

- The global mirror coatings industry size reached USD 785.8 Million in 2024.

- The market is expected to reach USD 1,265.2 Million by 2033, exhibiting a growth rate (CAGR) of 5.35% during 2025-2033.

- Asia Pacific leads the market, accounting for the largest mirror coatings market share.

- Repair hand cream exhibits a clear dominance in the market due to their specialized formulations that address common skin issues like dryness and irritation.

- Generation X represents the largest segment because they are more likely to invest in skincare products that offer anti-aging and protective benefits.

- The increasing awareness about skincare and overall health among the masses is a major factor impelling the market growth.

-

The increasing trend of comprehensive personal care routines is supporting the market growth. As people become more conscious of self-care and wellness.

Industry Trends and Drivers:

- Technological Advancements in Coating Techniques:

Modern technologies such as sputtering, chemical vapor deposition (CVD), and physical vapor deposition (PVD) are improving the durability and performance of mirror coatings. These advanced methods allow for the application of uniform, thin, highly reflective coatings, improving the overall quality and lifespan of the mirror. Additionally, innovations in nanotechnology are enabling the development of coatings with superior properties, such as improved resistance to scratches, weathering, and corrosion. These technological improvements not only improve product performance, but also reduce production costs and environmental impact, making advanced coatings more accessible and attractive to a wider range of industries.

- Growing Demand in the Automotive Industry:

The growing demand for high-performance, aesthetically pleasing, and durable automotive mirrors is driving the market growth. Modern vehicles require advanced coatings on rearview, side, and interior mirrors to improve visibility, reduce glare, and enhance the overall driving experience. The increasing adoption of electric vehicles (EVs) and autonomous driving technologies has led to an increased need for mirrors that integrate electronic displays and sensors, further driving the demand for specialty coatings. Additionally, the trend towards lightweight materials in automotive design is driving the need for coatings that can adhere to a variety of substrates such as plastics and composites.

- Expansion in the Solar Energy Sector

Concentrated solar power (CSP) systems, which use mirrors to concentrate sunlight onto a small area to generate heat and electricity, rely heavily on high-performance mirror coatings to maximize efficiency and durability. These coatings must withstand harsh environmental conditions, including extreme temperatures, ultraviolet (UV) radiation, and sand abrasion, while maintaining high reflectivity. As global efforts to fight against climate change intensify, investment in renewable energy sources like solar power is increasing, leading to greater adoption of CSP technologies. This trend is further supported by government incentives and policies promoting clean energy. Moreover, the need for advanced mirror coatings that enhance the efficiency and longevity of solar energy systems is supporting the market growth.

Request for a sample copy of this report: https://www.imarcgroup.com/mirror-coatings-market

Mirror Coatings Market Report Segmentation:

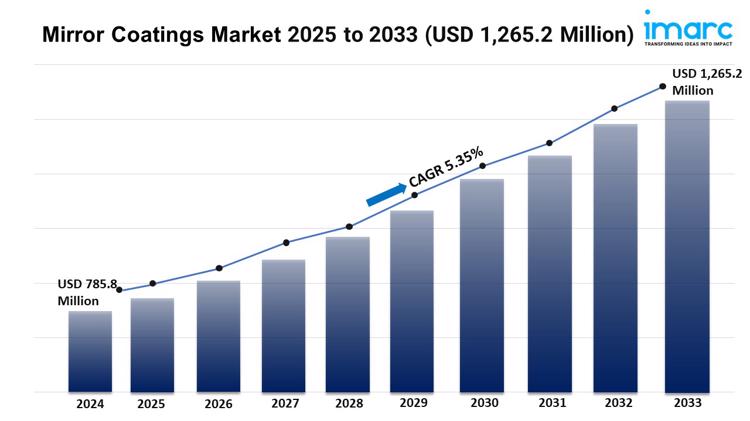

By Resin Type:

- Epoxy

- Acrylic

- Polyurethane

- Others

Polyurethane resin represents the largest segment, owing to its superior durability, flexibility, and resistance to environmental factors.

By Technology:

- Nano Coatings

- Solvent-Based

- Water-Based

Solvent based exhibits a clear dominance in the market due to their established application processes and ability to provide high-quality finishes with consistent performance.

By Substrate:

- Silver

- Aluminium

- Others

Aluminum accounts for the majority of the market share, driven by its lightweight, high reflectivity, and cost-effectiveness, which make it ideal for a wide range of mirror applications.

By End User:

- Building and Construction

- Automotive and Transportation

- Energy

- Others

Building and construction hold the biggest market share, driven by the extensive usage of mirror coatings for both functional and decorative purposes.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific's dominance in the mirror coatings market is attributed to the rising investment in infrastructure development projects.

Top Mirror Coatings Market Leaders:

The mirror coatings market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- Arkema S.A., CASIX (Fabrinet)

- Diamon-Fusion International Inc.

- Dynasil Corporation

- Edmund Optics Inc.

- FENZI S.p.A.

- Ferro Corporation

- Guardian Glass LLC (Koch Industries Inc.)

- Pearl Nano LLC

- The Sherwin-Williams Company

- Tianjin Xin Lihua Color Materials Co. Ltd (NBC)

- Vitro S.A.B. de C.V.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) 91 120 433 0800

United States: 1-631-791-1145 | United Kingdom: 44-753-713-2163